Expert Hydraulic Cylinder Repair Near Me: Your Ultimate Guide

Are you in urgent need of reliable hydraulic cylinder repair services? When your equipment's hydraulic cylinders falter, the entire operation can grind to a halt, leading to costly downtime and missed deadlines. Finding a trustworthy, expert service for hydraulic cylinder repair near me is not just about convenience; it's about ensuring your machinery operates at peak performance, safely and efficiently. This comprehensive guide will walk you through everything you need to know about professional hydraulic cylinder repair, helping you make an informed decision for your business.

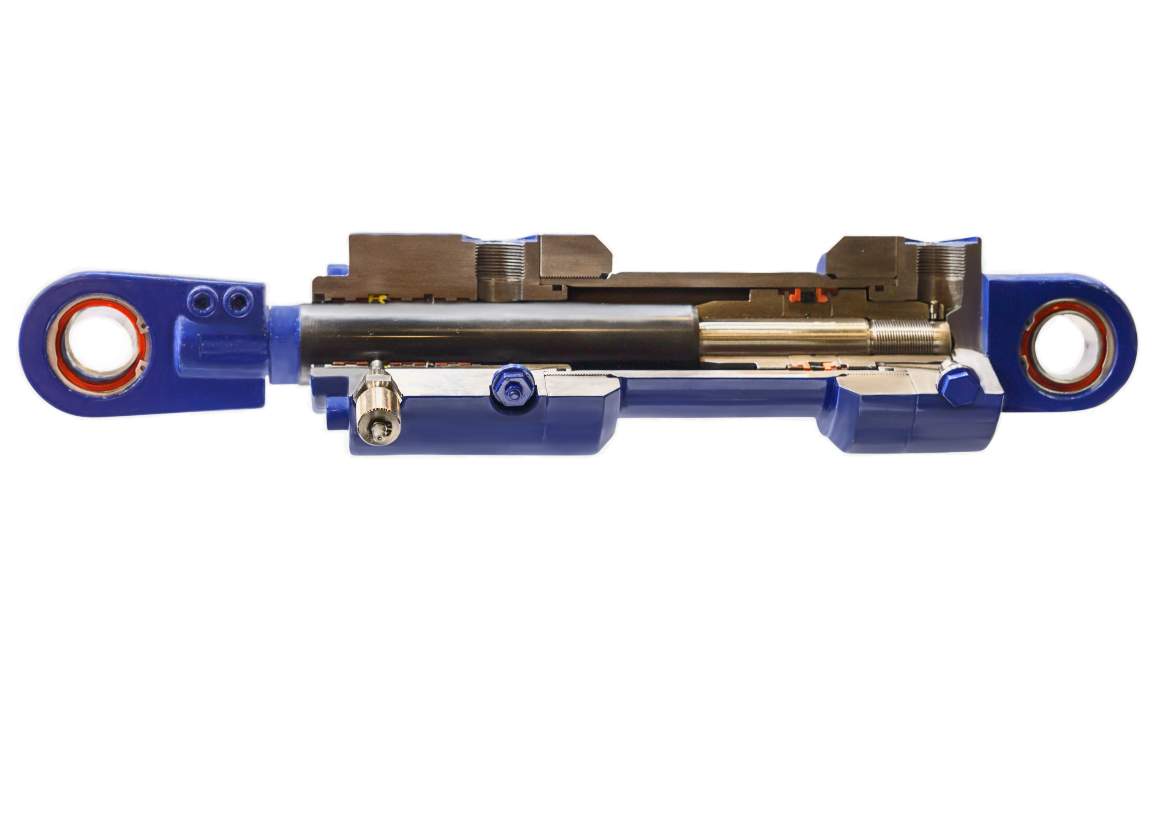

From construction sites to manufacturing plants, agricultural fields to marine vessels, hydraulic cylinders are the unsung heroes powering countless heavy-duty applications. Their robust design allows them to withstand immense pressure and perform critical tasks, yet like any mechanical component, they are subject to wear and tear, leaks, and eventual failure. Understanding the signs of a failing cylinder and knowing where to turn for quality repair can save you significant time and money, extending the lifespan of your valuable assets and maintaining operational continuity.

Table of Contents

- Why Hydraulic Cylinder Repair is Crucial for Your Operations

- Common Issues Requiring Hydraulic Cylinder Repair

- What to Look For in a Hydraulic Cylinder Repair Service

- The Repair Process: From Evaluation to Restoration

- Benefits of Professional Hydraulic Cylinder Repair

- Finding the Right Hydraulic Cylinder Repair Near You

- Beyond Cylinders: A Holistic Approach to Hydraulic Maintenance

- Ensuring Quality and Trust in Your Repair Partner

Why Hydraulic Cylinder Repair is Crucial for Your Operations

Hydraulic cylinders are fundamental components in a vast array of industrial and mobile equipment. They convert hydraulic power into linear mechanical force, enabling functions like lifting, pushing, pulling, and pressing. When a cylinder begins to malfunction, it's not just an inconvenience; it's a direct threat to productivity, safety, and profitability. An inefficient cylinder can lead to slower operations, increased fuel consumption, and potential safety hazards. Moreover, ignoring minor issues can quickly escalate into catastrophic failures, leading to extensive damage to the entire hydraulic system or even the machine itself. Investing in timely and professional hydraulic cylinder repair is a proactive step that ensures your machinery continues to perform optimally. It prevents minor leaks from becoming major system failures, mitigates the risk of accidents due to compromised equipment, and ultimately safeguards your operational budget by avoiding the much higher costs associated with complete cylinder replacement or extensive system overhauls. For expert hydraulic cylinder repair that restores performance and extends service life, choosing a reputable service provider is paramount.Common Issues Requiring Hydraulic Cylinder Repair

Hydraulic cylinders are subjected to extreme pressures, heavy loads, and often harsh environmental conditions, making them susceptible to various forms of wear and damage. Recognizing the common signs of trouble can help you address issues promptly and prevent further complications. Typical problems that necessitate professional hydraulic cylinder repair include:- **Leaking Seals:** This is perhaps the most common issue. Worn, cracked, or hardened seals allow hydraulic fluid to escape, leading to pressure loss, reduced efficiency, and potential environmental contamination. Leaks can occur internally (bypassing fluid) or externally (visible drips).

- **Scored or Damaged Rods/Bores:** The piston rod or the cylinder bore can become scratched, pitted, or bent due to impact, abrasive particles in the fluid, or improper lubrication. This damage compromises seal integrity and can lead to internal leakage and inefficient operation.

- **Bent or Broken Components:** Piston rods can bend under excessive side loads, while clevises, mounts, or other structural components can break due to fatigue or impact.

- **Contamination:** Dirt, debris, water, or even degraded hydraulic fluid can contaminate the system, leading to abrasive wear on internal components and premature seal failure.

- **Corrosion:** Exposure to moisture or corrosive chemicals can lead to rust and pitting on metal surfaces, particularly on the piston rod, which can damage seals and compromise structural integrity.

- **Loss of Power or Speed:** If a cylinder is operating slower than usual or struggling to lift its rated load, it often indicates internal leakage, worn components, or issues with the hydraulic fluid itself.

What to Look For in a Hydraulic Cylinder Repair Service

When searching for "hydraulic cylinder repair near me," it's crucial to evaluate potential service providers based on several key criteria to ensure you receive quality, reliable, and cost-effective solutions. The right partner can make a significant difference in your operational uptime and long-term savings.Expertise and Experience

The foundation of reliable repair is deep expertise. Look for companies that explicitly state their specialization in hydraulic repairs, particularly cylinders and pumps. Their team of experts should be both experienced and qualified to deal with hydraulic cylinder diagnostics and repair tasks of any complexity. A reputable shop will have skilled technicians equipped to handle all your hydraulic cylinder repair needs, understanding the nuances of different cylinder types, sizes, and applications. They should be able to refurbish/repair your hydraulic cylinder regardless of type, length, size, or diameter. Some even specialize in large rod and bore cylinders, stocking chrome rod sizes up to 8” and honed tube material up to 12”, demonstrating their capability for heavy-duty requirements.Comprehensive Service Offerings

A top-tier hydraulic repair shop offers more than just basic repairs. They should provide a full range of services that address the entire hydraulic system. This includes:- **Complete Hydraulic System Rebuild and Repair:** Not just cylinders, but also pumps, motors, and transmissions.

- **Custom Cylinder Manufacturing:** The ability to repair your obsolete cylinder or even build a new custom cylinder for you from scratch if needed, especially in cases of catastrophic damage where manufacturing a brand new unit is more cost-effective.

- **Hose and Fittings:** A full line of hydraulic hose, fittings, and adapters, as these are often interconnected with cylinder issues.

- **Preventive Maintenance:** Services like fluid power preventive maintenance can help identify potential issues before they become major problems.

- **On-site and In-field Solutions:** For larger equipment or emergency situations, companies that provide onsite and in-field solutions can be invaluable.

- **Specialization in Brands/Industries:** Some shops specialize in the overhaul and reconditioning of leading brands of hydraulic components or cater to specific industries like aggregate, mining, oil, natural gas, petroleum, livestock, and transportation.

The Repair Process: From Evaluation to Restoration

A professional hydraulic cylinder repair service follows a structured process to ensure thoroughness, quality, and lasting results. This systematic approach is key to getting your hydraulic cylinder back to like-new working condition. 1. **Initial Assessment and Evaluation:** The process begins with a comprehensive evaluation. This involves a detailed inspection of the cylinder to identify the root cause of the failure. Technicians will look for external damage, signs of leaks, and assess the overall condition. Many reputable shops offer free estimates, and some even provide free pickup or delivery services, making the initial step convenient for you. 2. **Disassembly and Inspection:** The cylinder is carefully disassembled, and each component – rod, barrel, piston, seals, glands, etc. – is thoroughly cleaned and inspected for wear, damage, or defects. This is where expertise truly shines, as technicians can spot subtle issues that might be overlooked by less experienced hands. 3. **Component Repair or Replacement:** Based on the inspection, damaged parts are either repaired or replaced. This might involve: * **Honing the cylinder barrel:** To restore the internal surface and ensure proper sealing. * **Chroming or machining the rod:** To repair scoring or wear, or even machining an entire cylinder from scratch if needed for severe damage or custom requirements. * **Replacing seals and bearings:** Always with high-quality, durable materials. * **Fabricating new components:** For obsolete parts or custom needs, some facilities have machine shops capable of manufacturing new parts. 4. **Reassembly:** The cylinder is meticulously reassembled, with new seals and components installed according to manufacturer specifications and best practices. 5. **Testing:** This is a critical phase. Our team of experts thoroughly tests all our repairs to make sure they meet or exceed OEM specifications. This often involves pressure testing to detect any leaks and ensure the cylinder operates correctly under load, guaranteeing optimal performance and safety before it leaves the facility. 6. **Quality Assurance and Warranty:** Reputable repair services provide a warranty on their work, typically a 1-year warranty, demonstrating confidence in their quality workmanship. This full warranty coverage gives you peace of mind. This detailed process ensures that whether it's a simple cleaning or reseal or a thorough repair, the solution is tailored to meet your needs, restoring performance and extending service life.Benefits of Professional Hydraulic Cylinder Repair

Choosing professional hydraulic cylinder repair over attempting DIY fixes or immediate replacement offers significant advantages, particularly in terms of cost-effectiveness and equipment longevity.Cost-Effectiveness

One of the most compelling reasons to opt for professional repair is the substantial cost savings. Repairing a hydraulic cylinder is almost always more economical than purchasing a brand-new replacement. While the initial cost of a new cylinder might seem straightforward, it often overlooks factors like shipping, installation, and the potential for long lead times, especially for specialized or obsolete models. Save money with hydraulic cylinder repair from reputable services that offer reasonable prices without compromising on quality. In some cases of catastrophic damage to a hydraulic unit, it is more cost effective for us to manufacture a brand new cylinder, but even then, it's a calculated decision based on expert evaluation.Extended Equipment Life

Expert hydraulic cylinder repair services are designed to restore the cylinder to like-new working condition, often exceeding original specifications through the use of higher-quality materials or improved designs. This not only gets your equipment back to work quickly but also extends its overall service life. A properly repaired cylinder functions reliably, reducing future breakdowns and the need for frequent maintenance. This proactive approach to maintenance minimizes downtime, maximizes productivity, and protects your investment in heavy machinery. From leaky seals to complete rebuilds, professional repair ensures you get back to work quickly with confidence.Finding the Right Hydraulic Cylinder Repair Near You

The search for "hydraulic cylinder repair near me" can be simplified by knowing where to look and what questions to ask. The goal is to find a local partner who offers fast, reliable service and understands the urgency of your operational needs. 1. **Online Search and Directories:** Simply by entering your zip code, you can find the nearest hydraulic repair services near you. Online maps and business directories are excellent starting points. Look for companies with strong reviews and a clear description of their services. 2. **Industry Referrals:** Ask colleagues, other businesses in your industry, or equipment dealers for recommendations. Word-of-mouth referrals often lead to the most reliable service providers. 3. **Specialized Shops:** Focus on shops that specialize in hydraulic repairs, hydraulic system services, and sales of hydraulic components. These are more likely to have the specific expertise and equipment needed for quality cylinder repair. 4. **Geographic Proximity and Service Area:** While "near me" is subjective, consider how quickly they can respond. Some companies offer fast turnaround and are strategically located to serve key industrial areas, such as those in Oklahoma City serving oil, natural gas, and petroleum industries, or those in North Carolina offering fast, reliable hydraulic cylinder repair. Others might be headquartered in specific regions like New Jersey, providing onsite and in-field solutions. 5. **Contact and Consultation:** Reach out for a comprehensive evaluation. Don't hesitate to ask about their experience, their repair process, warranty policies, and turnaround times. A good service provider will be transparent and willing to discuss your specific needs. Are you still searching for ‘hydraulic cylinder repair near me?’ Your search is over once you connect with a reputable local expert.Beyond Cylinders: A Holistic Approach to Hydraulic Maintenance

While hydraulic cylinder repair is a specialized service, it's often part of a larger ecosystem of fluid power maintenance. The most effective service providers adopt a holistic approach, understanding that a cylinder's performance is intrinsically linked to the health of the entire hydraulic system. Many leading repair shops specialize in complete hydraulic system rebuild and repair, including not just cylinders but also hydraulic pumps, motors, hydrostatic components, and transmission repair and testing. This comprehensive capability means they can diagnose issues that might originate outside the cylinder but affect its performance. For instance, a failing pump can cause a cylinder to underperform, or contaminated fluid can lead to premature seal wear. Furthermore, a full-service provider often stocks a full line of hydraulic hose, fittings, and adapters, ensuring that any related components can be replaced or repaired during the service. Some even offer recycle equipment repairs and welding services, providing a one-stop shop for various industrial maintenance needs. This integrated approach ensures that all hydraulic related components are in optimal condition, preventing recurring issues and maximizing the efficiency and longevity of your machinery. Contact us today for more details on our industrial repair services, as a truly comprehensive partner can repair anything and everything hydraulic related.Ensuring Quality and Trust in Your Repair Partner

When your livelihood depends on the reliable operation of heavy machinery, the quality and trustworthiness of your hydraulic cylinder repair partner are non-negotiable. It's not just about fixing a part; it's about restoring confidence in your equipment and ensuring safety and productivity. A reputable service will prioritize quality workmanship. This means using high-grade materials, employing certified technicians, and adhering to strict industry standards throughout the repair process. They will thoroughly test all repairs to make sure they meet or exceed original equipment manufacturer (OEM) specifications, ensuring that the repaired cylinder performs as good as, if not better than, new. Transparency is another hallmark of a trustworthy provider. They should offer free estimates and clearly communicate the scope of work, expected costs, and turnaround times. A 1-year warranty on their work is a strong indicator of their commitment to quality and customer satisfaction. This warranty provides peace of mind, knowing that the repair is guaranteed. At JMG Hydraulic Repair, you can be confident that we will provide not only the highest quality service but also a partnership built on trust and reliability. M & M Hydraulic Company, for instance, offers all types and sizes of hydraulic cylinder repair, specializing in the overhaul and reconditioning of leading brands of hydraulic components, including power units, showcasing their deep expertise. For quality hydraulic and pneumatic service and repairs, please contact us today. We'll quickly find a repair solution to meet your needs, whether it's a simple cleaning or reseal or a thorough repair, ensuring your equipment is back in action swiftly and safely.Conclusion

In the demanding world of heavy machinery and industrial operations, the efficiency and reliability of your hydraulic cylinders are paramount. When faced with a malfunctioning cylinder, the search for "hydraulic cylinder repair near me" leads to a critical decision that impacts your bottom line and operational continuity. We've explored the common issues that necessitate repair, the crucial criteria for selecting a service provider, the meticulous repair process, and the undeniable benefits of professional intervention. Choosing an expert hydraulic cylinder repair service means investing in quality workmanship, fast turnaround, and long-term savings. It means partnering with a team that offers comprehensive evaluations, can repair obsolete cylinders or build custom ones, provides a full warranty, and understands the urgency of getting your equipment back to work. Don't let a failing hydraulic cylinder halt your progress. Reach out for a comprehensive evaluation from a trusted local expert today. If you have any questions or need immediate assistance, please feel free to contact us. Share this guide with anyone who might benefit from understanding the value of professional hydraulic cylinder repair, and explore our other articles for more insights into maintaining your valuable equipment.

hydraulic cylinder repair companies near me - Donnie Whitson

Hydraulic Cylinder Repair - Apex Hydraulics

Hydraulic Cylinder Repair Near You - Precision Fluid Power